Shandong Dehai Youli New Energy Co., Ltd. is a national high-tech enterprise integrating research, development, manufacturing and sales of special industrial belts, photovoltaic silicon panels, rail transit and spacecraft solar wing accessories. The company has passed the ISO international quality system certification. We have a standard quality control system in place and always follow a standardized laboratory.

A general view of the laboratory

The laboratory simulates the production of small test equipment

I: Quality Control

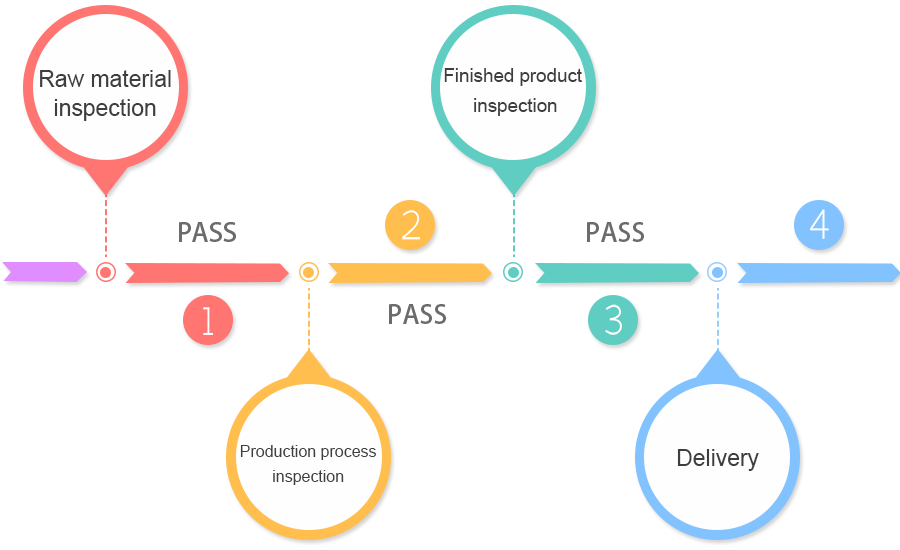

Product quality control process:

There are specific inspection standards for each item of raw materials, semi-finished products and finished products. The quality inspector shall conduct inspection in accordance with relevant inspection specifications and issued after passing the inspection.

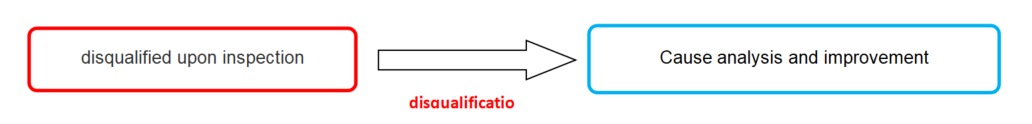

1.Raw materials: control the quality of compound inspection and auxiliary materials inspection

We are very strict with suppliers, including their enterprise qualification, production capacity, quality system control, quality assurance of raw materials, technical strength, supply cycle, transportation and freight, as well as future quality issues, response speed, service status and evaluation of cooperation results. All incoming raw materials must be attached with the supplier's inspection report, and then qualified by the quality inspection personnel before they can be put into production.

2.Process inspection: quality inspectors track and monitor, the workshop strictly carries out the transfer of qualified products in accordance with the mutual inspection, and strictly operates in the whole process

3. inspection of finished products: final inspection of all products including appearance, size, thickness, performance, etc. The goods can only be delivered after being inspected by the quality inspector

4. According to the product inspection situation. Daily summary analysis feedback, weekly production quality analysis meeting, monthly comparison analysis meeting again, and annual meeting summary. So that the production department and related departments can always be clear at a glance the quality of the production of products so as to take appropriate measures in time.

5. Timely analyzed the abnormal problems with technology and production and took improvement measures to improve the quality steadily. To prevent the recurrence of similar problems, and effectively improve the quality of products.

6.Check and analyze technical and production issues and take corrective actions to ensure the quality of products

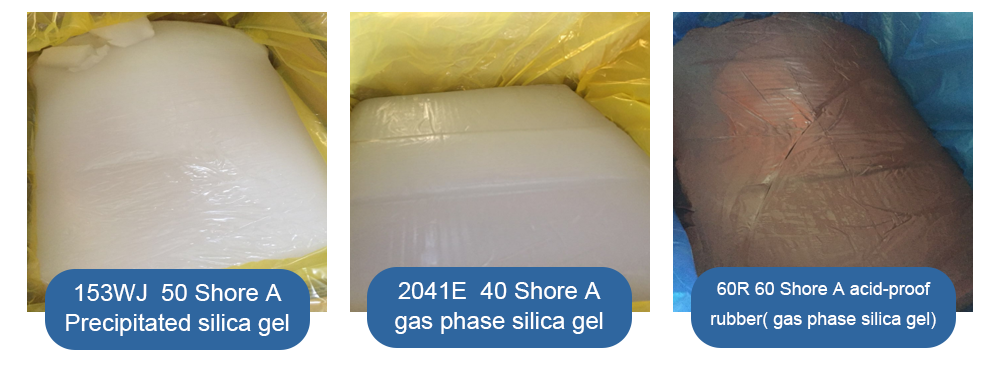

II: Silica gel industry related testing projects:

1. Raw material testing

①Silica gel mixture (including ordinary precipitation silica gel and high tear gas phase silica gel), each batch of rubber material are required to do mechanical properties testing: tensile strength, elongation, tear strength, hardness).

A small machine for testing samples

②Silica gel temperature resistant agent, each batch in accordance with the testing procedures are tested.

③Silica gel vulcanization agent, each batch in accordance with the testing procedures are tested.

④Silica gel masterbatch, combined with technology for related detection, to ensure the stability of product quality. (Contrast test)

⑤Silica gel plate mesh cloth, appearance testing, mechanical properties testing.

⑥Silica gel vulcanized cloth (polyester cloth), each roll in accordance with the testing procedures are tested.

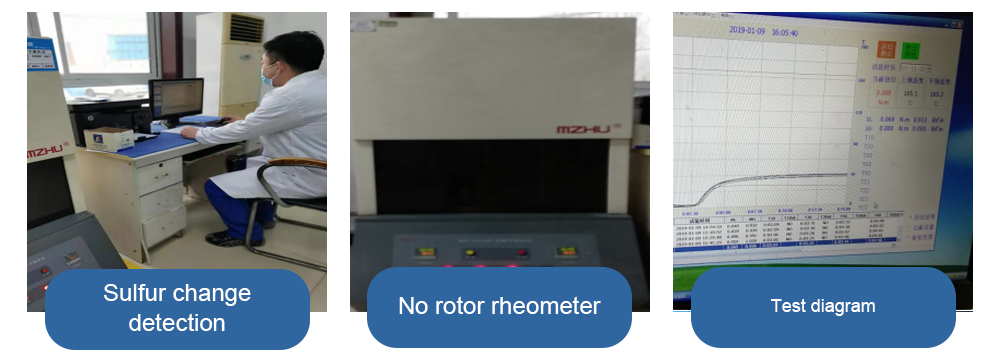

2.Process control

Production equipment list

①Testing of adding sulfur and color to silica gel mixtures

②Testing of mechanical properties of silica gel mixtures.

③24H monitoring and supervision of the production process and on-site inspection must be conducted in accordance with the production process.

3.Finished product testing.

①Silica gel plate products: the first online confirmation, testing tensile properties, tearing properties, hardness.

Silica gel plate finished product workshop: appearance, size, thickness test.

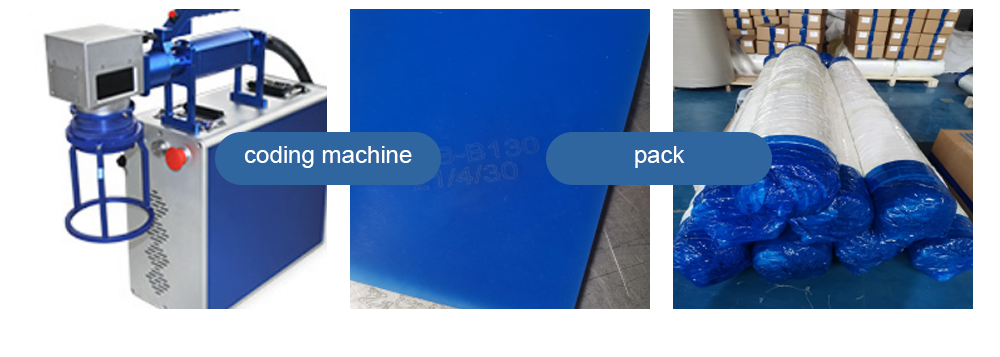

Silica gel plate finished product code, packaging and delivery.

②Silica gel sleeve vacuum test: 100% full test.

③Silica gel strip appearance and specification inspection: must meet the test indicators.